A new report from La Sapienza University of Rome has been published on the characterization of recycled polypropylene

.

.

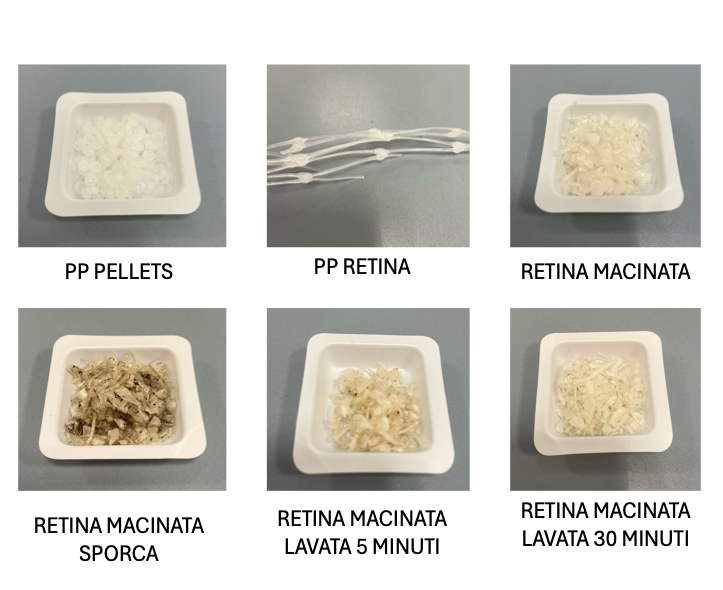

In order to verify the possible recycling of polypropylene socks, ROM Plastica carried out a preliminary mechanical recycling of these socks obtained by first shredding the material coming from the used socks (grinding), subsequently removing the organic contaminants, by washing with pressure water, subsequently centrifugation and drying of materials. The samples obtained in the different phases were characterized by UNIROMA using spectroscopic, thermal and mechanical techniques in order to verify whether the final characteristics of the recycled material were similar to the virgin polymer.

.

The document was drafted by Clarissa Ciarlantini, Iolanda Francolini and Antonella Piozzi of the Department of Chemistry, La Sapienza University of Rome.

.

The preliminary characterizations carried out allowed us to confirm that thermal and mechanical treatments have an impact but not significantly on the reuse of PP in the same supply chain. In fact, grinding and washing for 30 min appear to be able to restore the properties of PP necessary for the production of new socks.

.

The next actions to be carried out will focus on repeat the same type of physical characterization carried out so far on PP socks used and treated in the designed plant, as well as evaluate the mechanical properties of socks made with recycled PP to compare them with those made with virgin PP. For this purpose, it is necessary to develop a procedure that allows the mechanical properties to be measured directly on virgin or recycled PP socks, and not on samples obtained by thermocompression in order to provide the manufacturer directly with a standardized methodology and avoid degradation phenomena resulting from physical treatments necessary to carry out the specimens.